Revolutionizing Concrete with Carbon-Negative Artificial Sand

Mitsubishi UBE Cement Corporation (MUCC) has unveiled GX-e Beads™, a groundbreaking carbon-negative artificial sand designed to transform concrete. Made from calcium-rich wastes and by-products, GX-e Beads™ capture 80 to 250 kg of CO₂ per ton through MUCC’s proprietary accelerated carbonation technology. A low-carbon binder and a unique granulation and solidification process further ensure the final product is net carbon negative.

Manufactured using a dry, room-temperature process, GX-e Beads™ offer significant cost savings and require minimal space compared to conventional methods. When combined with ordinary Portland or blended cement, these fine aggregates deliver concrete with comparable—or even superior—strength and fresh properties, making them ideal for ready-mix and secondary concrete products.

This innovative material not only reduces the environmental impact of concrete but also sets a new standard for sustainable construction.

Origami-Inspired Formwork Revolutionizes Concrete Construction

Architecture student Lotte Scheder-Bieschin has developed an innovative formwork system, Unfold Form, that shapes strong vaulted concrete floors using far less material. Inspired by origami, this lightweight design employs flexible plywood strips and textile hinges arranged in a zigzag pattern to create a robust mold for pouring concrete. Weighing just 24 kg, Unfold Form can support up to 1 ton of concrete and is easily assembled with basic tools.

Leveraging principles of bending-active structures and curved-crease folding for added rigidity, Scheder-Bieschin’s Unfold Form has already been used to construct vaulted floors at ETH Zurich and in Cape Town, South Africa. This novel approach not only reduces the need for concrete and steel but also promises faster, more affordable construction—ideal for sustainable development in regions around the world while reducing greenhouse gas emissions from traditional building practices.

Full story: https://newatlas.com/architecture/unfold-form-framework/

CarbonCure and MIT’s Masic Lab Launch Research Collaboration

CarbonCure Technologies and MIT’s Masic Lab are joining forces to advance our understanding of CO₂ mineralization within concrete—a key strategy in reducing the construction industry’s carbon footprint. Led by MIT Associate Professor Admir Masic at the Concrete Sustainability Hub, this collaboration will employ advanced techniques like in-situ Raman spectroscopy and microscopy to explore the kinetics of CO₂ mineralization, the formation of calcium carbonates, and improvements in cement hydration efficiency.

Concrete production is responsible for about 7% of global carbon emissions, making innovative CCUS (carbon capture, utilization, and storage) solutions essential. By diving deep into the nanochemomechanics of concrete, the research aims to optimize CO₂ injection processes, enhance the performance of carbon mineralized concrete, and accelerate the industry’s journey toward carbon neutrality.

As CarbonCure and MIT work together, their findings promise to not only strengthen the scientific foundation behind CO₂ mineralization but also drive practical improvements for concrete producers worldwide, paving the way for more sustainable infrastructure solutions.

Turning Solar Waste into Sustainable Concrete

Boral is pioneering an Australian-first initiative by using crushed glass from recycled solar panels as a partial replacement for natural sand in concrete production. In collaboration with solar panel upcycling company Elecsome, Boral has developed concrete mixes incorporating up to 50% solar glass sand for Victoria’s $26.1 billion North East Link road and tunnel project.

Test batches of the innovative concrete have been successfully transported and laid on-site, demonstrating excellent plastic and hardened properties that meet industry standards. This breakthrough offers a sustainable solution for repurposing end-of-life solar panels while reducing reliance on natural sand.

Boral’s Head of Sustainability and Innovation, Ali Nezhad, sees this as a key step toward building a circular economy in construction. With concrete production accounting for about 8% of global carbon emissions, integrating recycled materials like solar glass sand could help the industry move toward more sustainable practices.

Supported by the University of Melbourne, this initiative highlights the potential for innovative materials to shape the future of concrete while minimizing environmental impact.

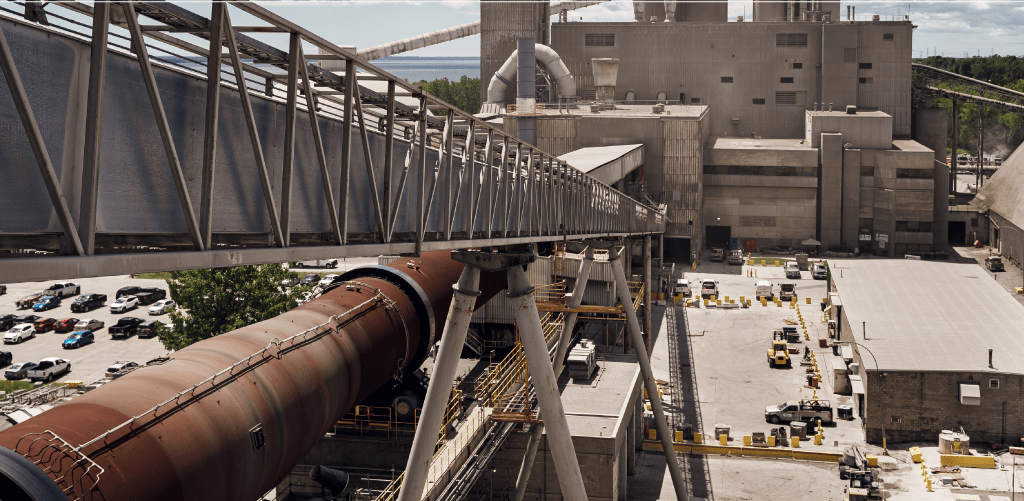

Decarbonizing Concrete with Innovative CO₂ Mineralization

A Lafarge cement plant in Ontario is leading the way in reducing concrete’s carbon footprint. In a pilot project with Hyperion Global Energy Corp., the plant has demonstrated a novel technology that captures CO₂ emissions from its stack and transforms them into high-purity precipitated calcium carbonate—an essential component in low-carbon concrete.

Using Hyperion’s patented Tandem Carbon Recycling (TCR) system, housed in a modular 40-foot shipping container, the plant currently removes 1,000 tonnes of CO₂ per year. Plans are underway to scale this up to 10,000 tonnes annually—a 500% increase—by 2025, with the potential to mineralize up to 50,000 tonnes of CO₂ per year across North American cement plants.

This innovative process not only creates sustainable, carbon-negative concrete products but also offers an affordable and scalable solution for the industry. By integrating such advanced decarbonization technologies, Lafarge aims to pave the way toward net-zero concrete production, transforming waste emissions into valuable, market-ready building materials.

Let me know what you think of these hot topics and any others you have come across!

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a comment