Concrete has often gone beyond its traditional role in construction to take on surprising, even heroic roles throughout history. From massive “Sound Mirrors” along Britain’s coast designed to detect enemy aircraft to reinforced concrete armor on Soviet tanks, this material has proven its adaptability in defense and transportation. Engineers and innovators have stretched the limits of concrete, using it to safeguard coasts, protect military assets, and even build seaworthy ships. This post uncovers some of the most unexpected applications of concrete, showcasing how this seemingly ordinary material has helped shape extraordinary moments in history.

1. The Concrete Giants of the British Coast: Sound Mirrors of the 1930s

Standing tall against the English coastline, monumental concrete “Sound Mirrors” were once Britain’s front line of defense against potential aerial attacks. Designed in the 1920s and 30s, these massive, concave structures—some as large as 60 meters across—were constructed to detect the low hum of approaching enemy aircraft engines. By concentrating sound waves at a focal point, these acoustic mirrors allowed early detection before aircraft could be seen or heard by conventional means.

William Sansome Tucker, a physicist with the Royal Engineers, led the creation of these “Giant Ears” near Kent, strategically placed along the coast to track incoming planes. The technology was promising, but as aircraft became faster and background noise from urban areas grew, challenges emerged. By 1935, radar technology was developed, ultimately replacing the sound mirrors and rendering the concrete giants obsolete.

Today, these structures remain as historical artifacts—a testament to an era when concrete architecture met innovative military science. Although no longer functional, the mirrors stand as resilient reminders of a time when concrete engineering aimed to protect Britain’s skies.

Capel-le-Ferne. Photo credit: Rob Riddle

2. Concrete Cargo Ships: A Forgotten Chapter in Maritime History

Concrete might not be the first material that comes to mind for cargo ships, but for a time, these solid vessels sailed the world’s oceans. The first concrete boat was built in 1848 by French innovator J.L. Lambot using “ferrocement,” a precursor to modern ferro-cement, where concrete is poured over a steel mesh frame.

During World War I, the scarcity of steel and the urgent need for durable cargo vessels led the United States to explore the unorthodox idea of building ships from concrete. Although concrete might seem an unlikely choice for seafaring vessels, engineers recognized that this strong, versatile material could substitute for steel when resources were limited.

One of the first practical concrete ships was the 84-foot Namsenfjord, created by Norwegian engineer N.K. Fougner. Fougner, a pioneer in concrete shipbuilding, demonstrated the material’s potential for large-scale, durable construction on water. The success of the Namsenfjord sparked further interest in concrete vessels, and shortly afterward, San Francisco businessman William Leslie Comyn took this concept to new heights with the construction of the Faith. At the time, the Faith was America’s largest concrete ship, measuring 336 feet in length.

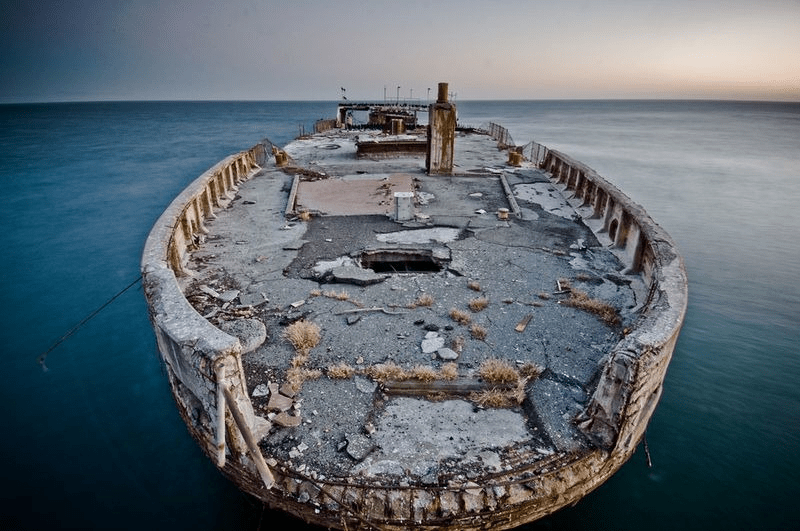

Despite initial skepticism, the Faith proved her seaworthiness, carrying cargo across the oceans on multiple voyages. She became a symbol of ingenuity during a time of material shortages, demonstrating that concrete could hold up against the demands of open-sea travel. However, as steel became more accessible in the post-war years, concrete ships became less economical, and many were eventually repurposed. The Faith, for example, found new life as a breakwater off the coast of Cuba, where her sturdy structure continued to serve as a protective barrier for years to come.

The development of concrete ships during World War I showcases an era of resourceful engineering, with concrete stepping in as a durable and adaptable solution for wartime needs. Although World War II briefly revived interest in concrete ships, their use was ultimately limited. As steel became more accessible, concrete cargo ships became economically unviable, with many later repurposed as breakwaters or piers as shown below.

![r/AbandonedPorn - Derelict concrete ships - literally ships made of concrete - forming a breakwater for a paper mill in Powell River, British Columbia [OC]](https://i.redd.it/qd5jhdk0wxq81.jpg)

3. Tsyganov’s Innovative Concrete Armor for Soviet Tanks

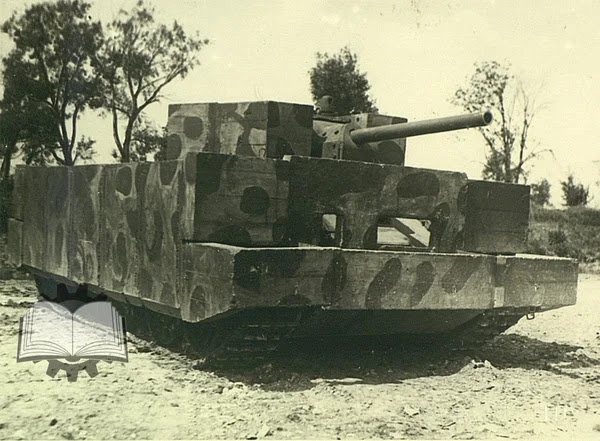

Engineer-Major Nikolai Fedorovich Tsyganov was a notable figure in Soviet tank engineering during the 1930s and WWII. Known for his work on the BT-IS and BT-SV tanks, Tsyganov continued his innovations during the war by developing additional armor to protect Soviet tanks from emerging German weapons. Among his designs, one of the most intriguing involved the use of concrete.

In 1943, Tsyganov created two types of additional armor designed to be easily produced and installed in field repair workshops. The first type used reinforced concrete blocks attached to the T-34 tank’s hull and turret. These concrete blocks were reinforced with metal ribs and bolted to the tank, leaving a gap between the concrete and the tank’s main armor. This spaced armor aimed to provide protection against high-explosive anti-tank (HEAT) shells and other threats. Although innovative, the concrete armor added over 9 tons to the tank, impacting its mobility.

Despite its weight, Tsyganov’s concrete armor demonstrated the engineer’s willingness to explore unconventional materials to meet wartime challenges. Although ultimately reserved for “special use” and not widely adopted, the concept of spaced armor found new life later, influencing tank armor developments during the Berlin operation. Tsyganov’s contributions to tank engineering, including his concrete armor, highlight his dedication to innovation and his impact on Soviet tank development. Tragically, he was killed in action in January 1945, but his legacy endures as a testament to Soviet engineering resilience during WWII.

From detecting distant aircraft along the British coastline to fortifying Soviet tanks and even crossing oceans as durable ships, concrete has played an unexpectedly vital role in moments of ingenuity and resilience. These historical uses remind us that concrete is far more than a static building material; it’s a symbol of adaptability and innovation. The unique applications we’ve explored here highlight how this humble material has risen to meet challenges across different eras and industries, shaping solutions that endure in both history and infrastructure. As we continue to develop new uses for concrete, we carry forward a legacy of creativity that proves there’s much more to concrete than meets the eye.

I’d love to hear your thoughts on these historical concrete applications, so please leave a like and comment below.

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a comment