End of an Era: Cemex Plant Transforms into 1000 La Brea Residences

After nearly a century, the iconic Cemex Hollywood Concrete Plant on La Brea Avenue has closed to make way for a new residential development. Located near Santa Monica Boulevard on the border of Los Angeles and West Hollywood, the plant was a relic among the upscale Sycamore District’s shops and galleries.

A 1924 issue of Concrete magazine called it “the pioneer mixing plant in the West,” supplying concrete for streets and landmarks, including movie studios. Upgraded over the decades, it played a key role through the post-World War II building boom.

In its final years, Cemex operated the plant, which became out of place as the area evolved. Developer CIM Group plans to replace it with 1000 La Brea, a 514-unit apartment tower with retail space, amenities, and 20% affordable units.

Full story: https://www.miamiherald.com/news/business/article295183169.html

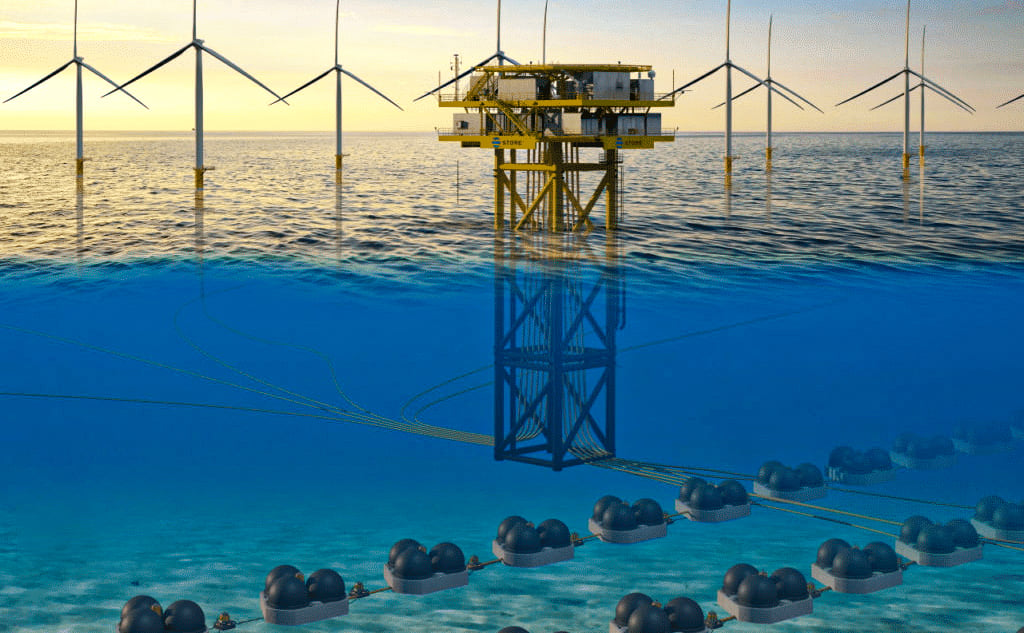

Sperra Secures Grant for 3D-Printed Concrete Domes in Subsea Hydropower

Sperra, formerly RCAM Technologies, received a $4 million grant from the US Department of Energy to develop 3D-printed concrete domes for subsea hydropower generation off Los Angeles. Partnering with Germany’s Fraunhofer IEE, supported by an additional $3.7 million, Sperra aims to harness marine energy, which could supply 57% of US power needs.

The project’s concrete spheres will store and release energy on the ocean floor. Production at the Port of Los Angeles will use sustainable, low-carbon, locally sourced 3D-printed concrete. Sperra highlights cost reduction, safety, and local economic benefits, while Fraunhofer emphasizes minimal ecological impact and broad acceptance for subsea energy storage.

Full story: https://all3dp.com/4/start-up-granted-millions-to-3d-print-concrete-domes-for-the-ocean-floor/

CarbonStar: New Standard for Low-Carbon Concrete

The Smart Surfaces Coalition, CSA Group, World Cement Association, and the American Public Health Association have launched CarbonStar, the first binational standard for measuring concrete’s carbon intensity. This standard, CSA/ANSI R118:2024, simplifies assessing embodied carbon in concrete, responsible for about 8% of global emissions.

Developed by industry, government, and academic experts, CarbonStar meets ANSI and Canadian standards and includes tools like a carbon intensity calculator for consistent measurement. Already adopted at San Francisco International Airport, it aids in specifying low-carbon concrete, supporting sustainable construction efforts and reducing climate impact.

Vattenfall’s Low-Carbon Concrete Initiative

Vattenfall’s Bruzaholm wind farm in Sweden is leading in carbon reduction with innovative concrete use. The project’s 21-turbine foundations use concrete with 211 kg of CO2 per cubic metre—40% lower than industry norms.

This low-carbon strategy supports Vattenfall’s goal of climate neutrality by 2040 and a 50% cut in supply chain emissions by 2030. With a modest cost increase under 2%, it sets a sustainable benchmark for future projects. The wind farm will produce 460GWh annually by 2025, showcasing impactful, eco-friendly construction.

Innovative Carbon-Storing Concrete Comes to London

Aggregate Industries UK and Swiss carbon removal firm neustark have partnered to integrate CO2 into recycled concrete at a new site in Greenwich, London. The project will inject 10kg of CO2 into each tonne of recycled concrete, potentially removing 1,000 tonnes of CO2 annually.

neustark’s mineralisation process permanently embeds liquefied CO2 sourced from biogas plants into demolished concrete, creating carbonated, reusable building materials. This approach supports a circular economy and combats construction’s significant carbon footprint—estimated to contribute 37% of global emissions.

With this technology, Aggregate Industries aims to reach net zero before 2050 and inspire other industry players to adopt sustainable practices, reinforcing the shift toward decarbonisation and innovative construction solutions.

Let me know what you think of these hot topics and any others you have come across!

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a comment