Bone-Inspired Cement: A New Era in Strong, Lightweight Construction

Princeton University researchers have developed a groundbreaking cement inspired by the structure of human bones. This material is not only lighter but also 5.6 times tougher than traditional concrete, resisting cracks and absorbing damage better. PhD candidate Shashank Gupta and professor Reza Moini based their design on cortical bone, using tubular structures to trap cracks and dissipate energy, preventing sudden failure.

Unlike other methods that add fibers or plastics, this cement achieves strength through its unique geometry, making it a potentially cost-effective, accessible solution for construction worldwide. Applications extend beyond infrastructure to aerospace and automotive industries, where lighter, tougher materials are essential.

Scaling production may involve robotic additive manufacturing, offering customization and precision for diverse construction needs. While further testing is needed, this bio-inspired cement points toward a resilient, sustainable future in building materials.

CarbonCure Reaches Major Milestone: 500,000 Metric Tons of CO₂ Saved

CarbonCure Technologies recently announced a major milestone, achieving over 500,000 metric tons of CO₂ savings through its carbon-utilization technology. This accomplishment is made possible by CarbonCure’s global network of concrete producers who incorporate captured CO₂ into fresh concrete, where it mineralizes, allowing for reduced cement use without sacrificing strength.

Beyond environmental benefits, CarbonCure’s approach generates economic value through cost savings and carbon credits, making it an attractive, scalable solution for the industry. With systems in over 25 countries, CarbonCure has already delivered more than 60 million cubic yards of lower-carbon concrete globally. This achievement not only reduces the embodied carbon in construction but also supports the industry’s shift toward a net-zero future.

Full story: https://www.carboncure.com/news/carboncure-achieves-half-million-metric-tons-of-carbon-savings/

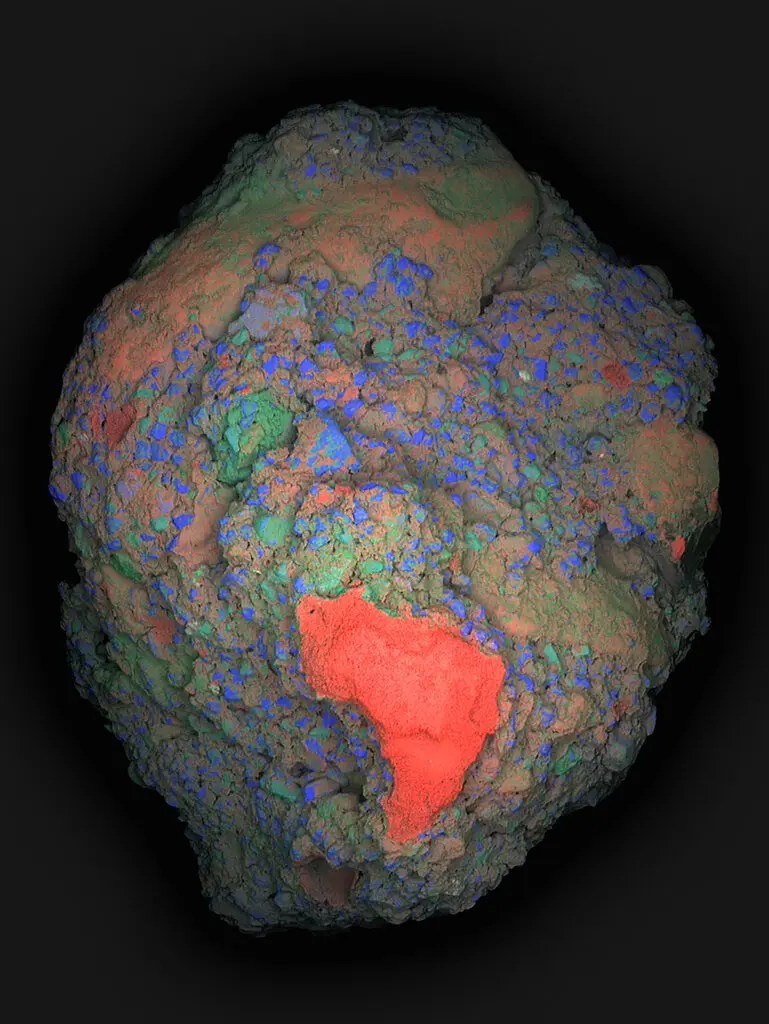

Japanese Researchers Create Carbon-Negative Concrete

Researchers from the University of Tokyo and Hokkaido University have created a concrete that absorbs more CO₂ than it emits, potentially transforming construction sustainability. Unlike traditional methods, which require high-temperature calcination and emit CO₂, this innovative process converts pulverized concrete waste into calcium carbonate by exposing it to CO₂, making the material carbon-negative.

Already meeting Japan’s building standards, this concrete could be commercially available by 2029. The team is now refining production and testing its use with structural components, paving the way for greener construction practices.

Full story: https://www.asahi.com/ajw/articles/15450173

Credit: Kai Ichino

Potato Skins: The Surprising Eco-Friendly Ingredient for Concrete

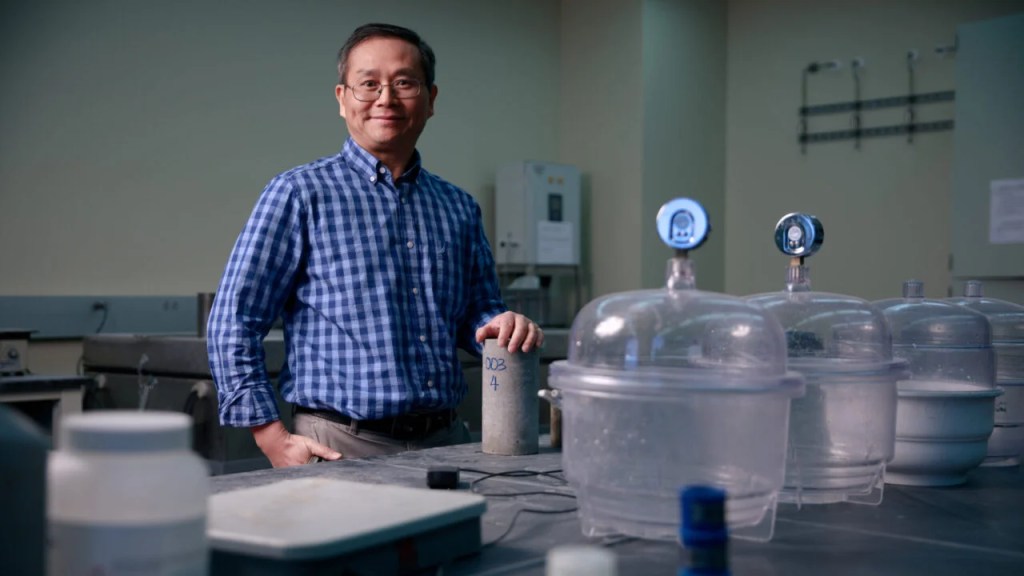

Researchers at The University of Alabama have developed a method to use potato skins as a sustainable component in concrete, offering a green alternative to traditional cement. Led by Dr. Jalai Wang, the team ferments potato peels to produce organic acids, which extract calcium from industrial waste. This calcium is then used to create calcium carbonate, a vital ingredient in cement, reducing CO₂ emissions and diverting waste from landfills.

With support from a $6 million NSF grant, this innovation benefits rural communities by generating demand for agricultural waste and tackling the environmental issues associated with coal ash disposal.

Credit: UA News Center

New York Times features MIT and DMAT’s research on Roman Concrete

Amos Zeeberg and the New York Times have featured the groundbreaking research by MIT chemist Dr. Admir Masic, who has unlocked the durability secrets of Roman concrete to enhance modern, sustainable construction. Masic’s findings reveal that the white clasts in Roman concrete, previously seen as imperfections, were actually purposeful additions of quicklime. These chunks release calcium when cracks appear, filling them with calcium carbonate to enable self-healing.

Using a “hot mixing” technique, the Romans achieved faster setting and remarkable durability. Inspired by this, Masic’s company, DMAT, is developing crack-sealing additives that provide a resilient, lower-carbon alternative to today’s concrete. This work demonstrates how ancient innovations can influence sustainable building practices in the modern era.

Full story: https://www.nytimes.com/2024/10/19/science/concrete-roman-construction.html

Let me know what you think of these hot topics and any others you have come across!

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a reply to inspiring280fac5fc7 Cancel reply