Meta Invests in Low-Carbon Concrete for Data Centers

Meta is investing in CarbonBuilt, a company producing Reversa®, a low-carbon concrete that replaces traditional Portland cement with a CO2-reactive alternative. This innovative product cuts carbon emissions by up to 70% while permanently storing CO2, without impacting performance or cost.

Meta’s funding will help upgrade two concrete plants in Arizona and Alabama, as the company seeks to reduce the carbon footprint of its data centers. The investment also aims to accelerate the adoption of sustainable concrete in the industry, addressing the challenges of scaling low-carbon solutions.

Full story: https://www.building.co.uk/news/meta-injects-cash-into-low-carbon-concrete-in-the-us/5131822.article

“Coffee concrete” used for the first time in a major infrastructure project

RMIT University’s innovative use of biochar made from spent coffee grounds has been applied in Victoria’s Big Build, where a footpath in Pakenham was constructed using “coffee concrete” to replace a portion of river sand. This sustainable solution diverts coffee waste from landfills, reducing greenhouse gas emissions and saving resources. For the project, 5 tonnes of coffee grounds—equal to 140,000 coffees—were converted into biochar, which strengthened 30 cubic meters of concrete. Led by Major Road Projects Victoria and BildGroup, this eco-friendly initiative is part of broader efforts to integrate circular economy practices in construction.

Full story: https://www.rmit.edu.au/news/all-news/2024/oct/coffee-concrete

Credit: Pete Glenane, HiVis Pictures

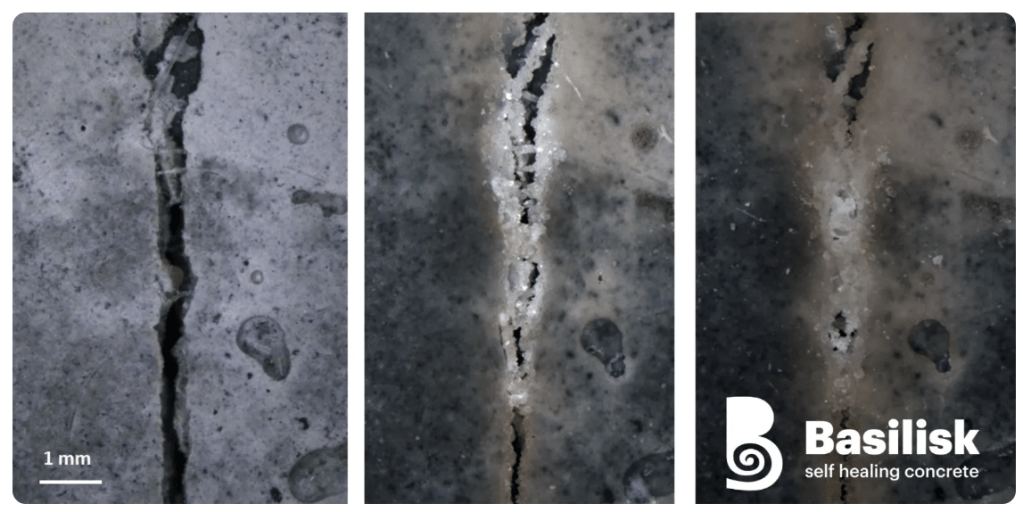

Self-Healing Concrete Debuts in the U.S., Revolutionizing Construction

A groundbreaking new material, Basilisk Self-Healing Concrete, has entered the U.S. market, offering a revolutionary solution for construction. Infused with bacteria, this concrete heals its own cracks by producing limestone, eliminating the need for traditional repairs. The result is a more durable and eco-friendly option with extended lifespan, lower maintenance costs, and reduced repair expenses.

By minimizing the need for repairs, Basilisk concrete helps cut CO2 emissions, reduces the need for steel reinforcements, and eliminates the requirement for waterproof coatings. This advancement is a major step forward in sustainable construction, offering both environmental and economic benefits. Along with other recent innovations like stronger hollow concrete and cement-free alternatives, self-healing concrete could reshape the future of building safety and significantly reduce the environmental impact of concrete production.

Full story: https://bgr.com/science/new-self-healing-concrete-that-fixes-its-own-cracks-is-now-being-used-in-the-us/

Lithium Byproducts Could Enhance Concrete Strength and Reduce Carbon Emissions

A German study shows that byproducts from lithium production, particularly leached spodumene concentrate (LSC), can replace fly ash in concrete, increasing its compressive strength by 10%. With fly ash supplies dwindling due to the decline of coal-fired power plants, LSC presents a sustainable alternative. This innovation not only boosts concrete performance but also reduces CO2 emissions, supporting efforts toward more eco-friendly construction. Rock Tech Lithium plans to use LSC in concrete production, helping the industry lower its environmental impact while enhancing material strength.

Full story: https://www.on-sitemag.com/construction/using-lithium-byproducts-in-cement-production/1003983336/

Low-Carbon Cement Used in Boston’s Largest Net Zero Office Building

Boston’s Seaport celebrated the first commercial use of Sublime Systems‘ low-carbon cement in a 707,000-square-foot office building leased to Amazon. Developed at MIT, Sublime’s cement eliminates CO2 emissions by avoiding the energy-intensive kiln process, offering a sustainable alternative for the construction industry.

Governor Maura Healey highlighted the importance of this innovation for decarbonizing the economy. Supported by $87 million from the Inflation Reduction Act, Sublime plans to expand in Massachusetts, including a new plant in Holyoke. Federal and state leaders are pushing for policies to further promote low-carbon materials in construction.

Image source: Turner Construction

Let me know what you think of these hot topics and any others you have come across!

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a comment