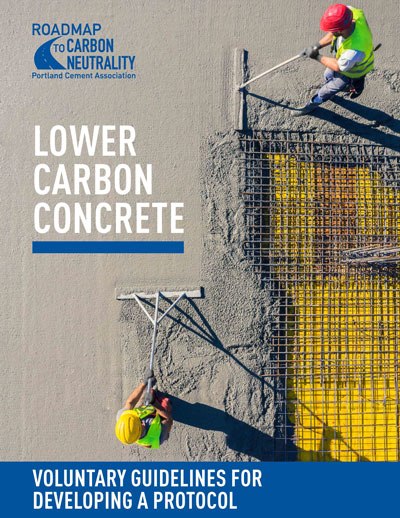

New PCA Guidelines for Lower Carbon Concrete

The Portland Cement Association (PCA) has released “Lower Carbon Concrete: Voluntary Guidelines for Developing a Protocol” to help reduce emissions in construction. Key points include:

- Use performance-based specs and allow equivalent material substitutions.

- Evaluate sustainability impacts across the full life cycle.

- Address risks with new materials and report both operational and embodied carbon.

PCA CEO Mike Ireland emphasizes a balanced approach to carbon neutrality, while Senior VP Rick Bohan highlights alternative fuels and low-carbon cements as key tools.

This resource offers practical steps for creating sustainable, resilient concrete.

Explore it here.

Conit Runner: A Game-Changer for Concrete Construction

A new robot, the Conit Runner, is set to revolutionize concrete construction by automating a critical process to boost strength and efficiency. Developed by Itone and Posco E&C, this innovative device grooves wet concrete to improve bonding between layers, reducing the need for costly rebar while enhancing structural integrity.

Key Benefits:

- Improved Strength: Grooves increase shear strength at layer interfaces, requiring up to 30% less rebar.

- Faster Construction: Speeds up projects by 85%, matching the output of eight workers.

- Precision: Uses advanced sensors and LiDAR to navigate, avoid obstacles, and optimize groove depth.

By automating this process, the Conit Runner makes concrete construction stronger, faster, and more cost-effective—paving the way for smarter, more sustainable building practices.

Full story: https://newatlas.com/robotics/conit-runner-concrete-construction-robot/

Building the Future: Sustainable Concrete with Microbial Materials

Cement production is responsible for 8% of global CO2 emissions, but groundbreaking research by Erika Espinosa-Ortiz, an environmental engineer at Utah State University, is offering a sustainable alternative. Espinosa-Ortiz is pioneering the use of bacteria and fungi in construction through a process called biomineralization, which creates cement-like materials with a lower carbon footprint.

How It Works:

- Bacteria-Based Biocementation: Ureolytic bacteria produce calcium carbonate, forming strong, cement-like structures. This method has already been used to create bio-bricks, a sustainable alternative to traditional concrete bricks.

- Fungal Innovations: Fungi could enable self-healing concrete by embedding spores that reactivate to repair cracks, making structures both durable and eco-friendly.

Espinosa-Ortiz’s work aligns with global efforts to decarbonize construction. With microbial materials already in use for tiles and bricks in Denmark, her research signals a promising future for sustainable building practices.

“We’re just beginning to understand how microbes can help us build the future,” she says. Through her work, Espinosa-Ortiz is paving the way for greener, more resilient concrete.

Source: Utah State University

MSU Researchers Develop Self-Healing, Flexible Concrete

A team at Michigan State University, led by Professor Qingxu “Bill” Jin and PhD student Antonio Ni, has developed an innovative self-healing concrete that could transform the industry.

This flexible concrete not only repairs itself but also generates heat, offering an eco-friendly solution for snow and ice removal on roads. By incorporating solid waste into its composition, this material reduces carbon emissions and promotes industrial decarbonization.

Professor Jin, an assistant professor in MSU’s College of Engineering, believes this technology has the potential to revolutionize the concrete industry. His students, Diego and Nathan, are also exploring ways to make this bendable concrete even more sustainable by utilizing solid waste for low-carbon solutions.

This breakthrough highlights MSU’s commitment to advancing sustainable construction technologies that address climate challenges.

GCCA Launches Global Low-Carbon Cement and Concrete Standards

At COP29, the Global Cement and Concrete Association (GCCA) introduced international definitions for low-carbon cement and concrete, using Environmental Product Declarations (EPDs) to provide a universal reference for identifying green materials. This move aims to accelerate sustainable construction and decarbonize the built environment.

Targets and Challenges:

- 2030 Goals: 20% CO2 reduction per tonne of cement and 25% per cubic meter of concrete (vs. 2020).

- Key Hurdle: Clinker production’s CO2 emissions, tackled through technologies like Carbon Capture, Utilization, and Storage (CCUS) and alternative materials.

GCCA CEO Thomas Guillot called for policymakers and businesses to prioritize green cement, supporting industry decarbonization. While CCUS shows promise, scalability and affordability remain challenges.

Green solutions are essential for cement and concrete to meet global Net Zero goals while sustaining modern infrastructure.

Full story: https://www.gasworld.com/story/international-low-carbon-cement-definition-agreed-at-cop29/2146909.article/

Let me know what you think of these hot topics and any others you have come across!

Also, don’t forget to subscribe to stay up to date with the latest concrete information.

Leave a comment